4. HOW TO CREATE NEW HARDWARE PRODUCTS. HARDWARE DESIGN TIPS.

Today we’re gonna continue to talk about HOW TO CREATE NEW HARDWARE PRODUCTS. In this part Alex Gudilko, CEO of AJProTech, is going to share our experience on hardware design and declassify some useful tips. Do not forget to share with your friends if you find it useful!

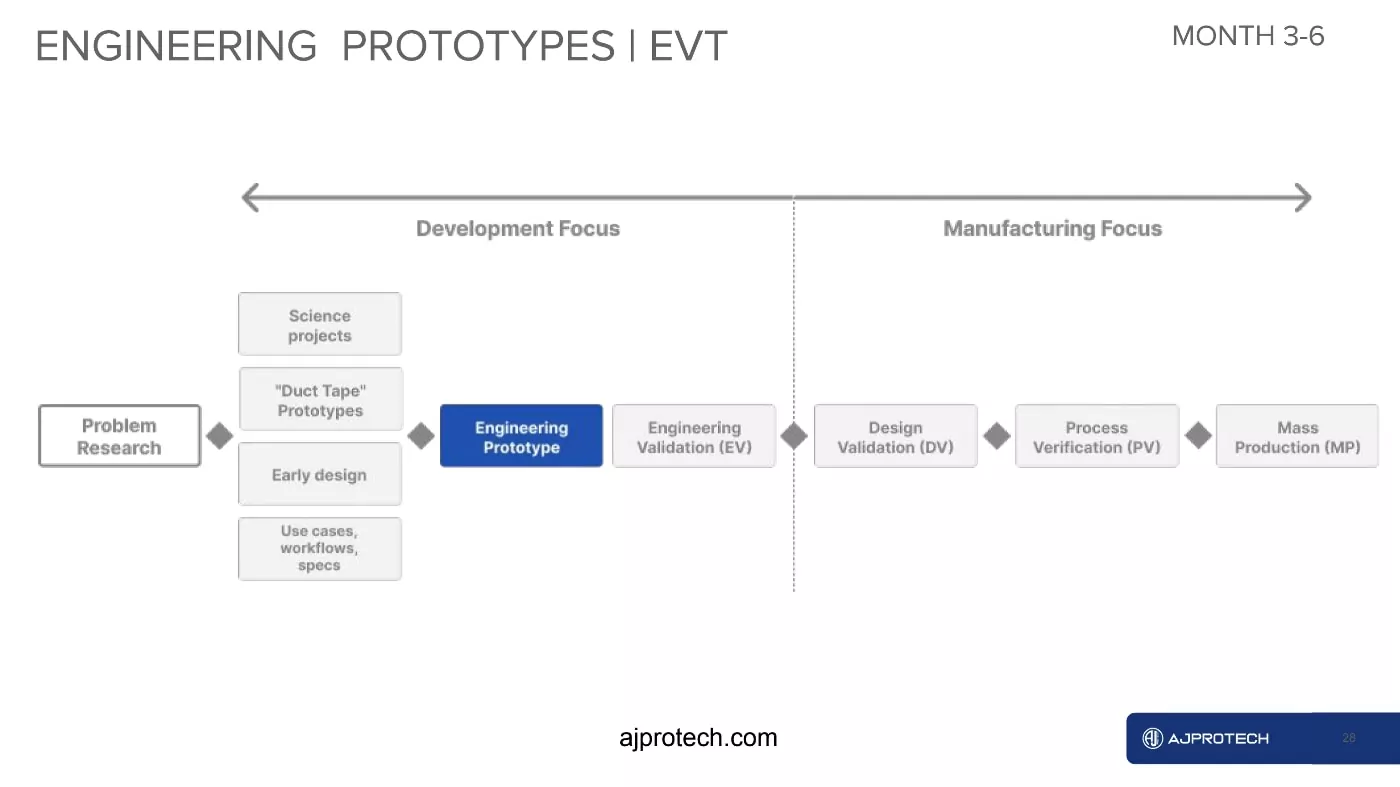

That was the Feasibility Study. On average, it takes us about 2 months from idea to know exactly what we are working on. Next step is Engineering Prototypes. This is the most intensive process for entire product development. It is followed by the Engineering Validation Test (EVT) at the end

Main goal on this stage is to validate all components. There is no tooling involved, no cost optimization, and unit cost is usually high. It’s a time when your first time customers can fully understand the product. It’s also the best time to raise money from investors. We usually create up to 5 prototypes, which can be shown to potential customers.

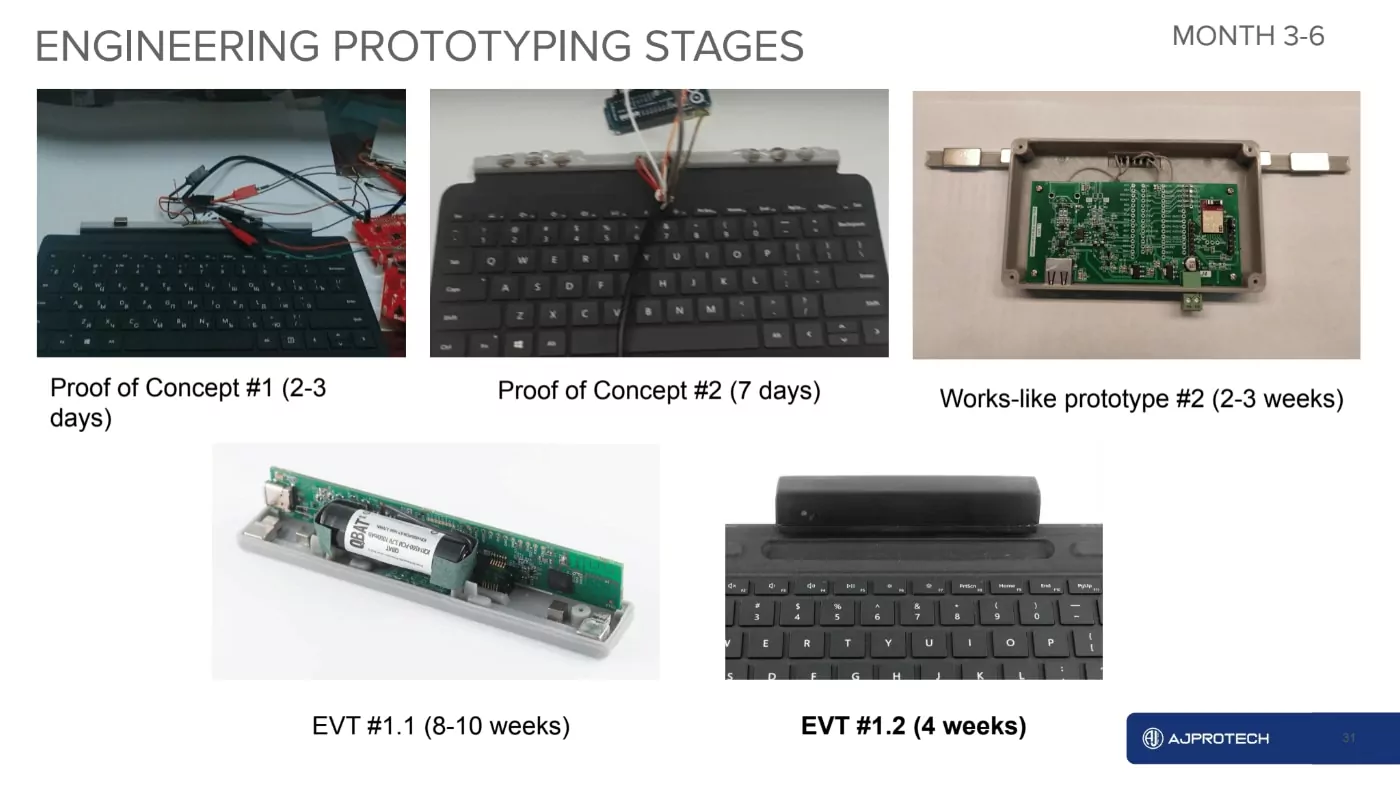

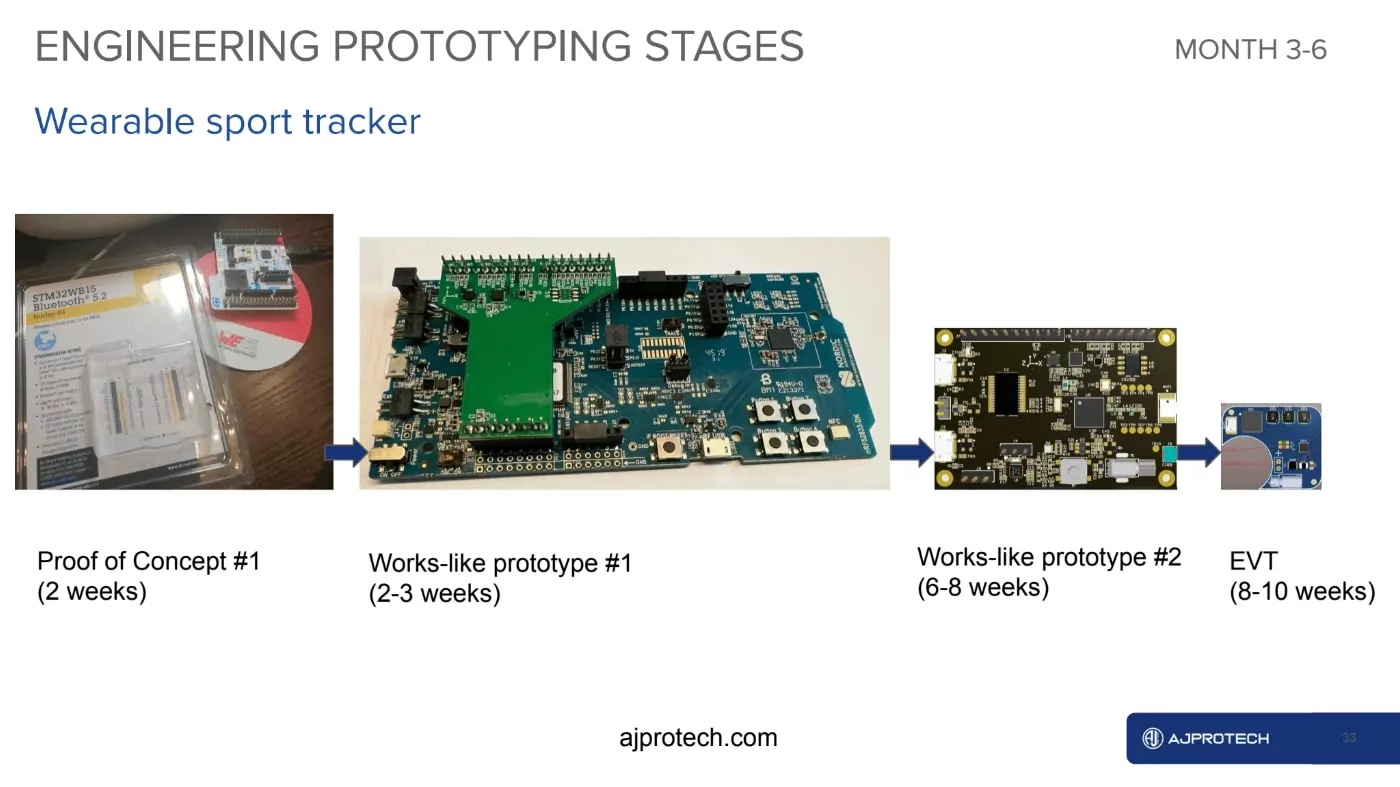

Typically you expect anywhere from 2 to 3 generations of PCB designed during prototyping. It’s fine to have some wiring as long as the device does its job.

Another recommendation to have for this phase is to add complexity gradually. There is no benefit of over-miniaturizing the device early on – it is going to be very hard to troubleshoot. Start big on the evaluation board and gradually make it smaller. Validate components, validate schematics, and then make the PCB of final size and shape. This way you don’t waste time & money if something goes wrong early on.

It’s OK to use some additional wiring on the prototypes, as long as they are functional, there is no need to be pretty here, the goal is to make it WORK.

Let me share some HARDWARE ENGINEERING tips:

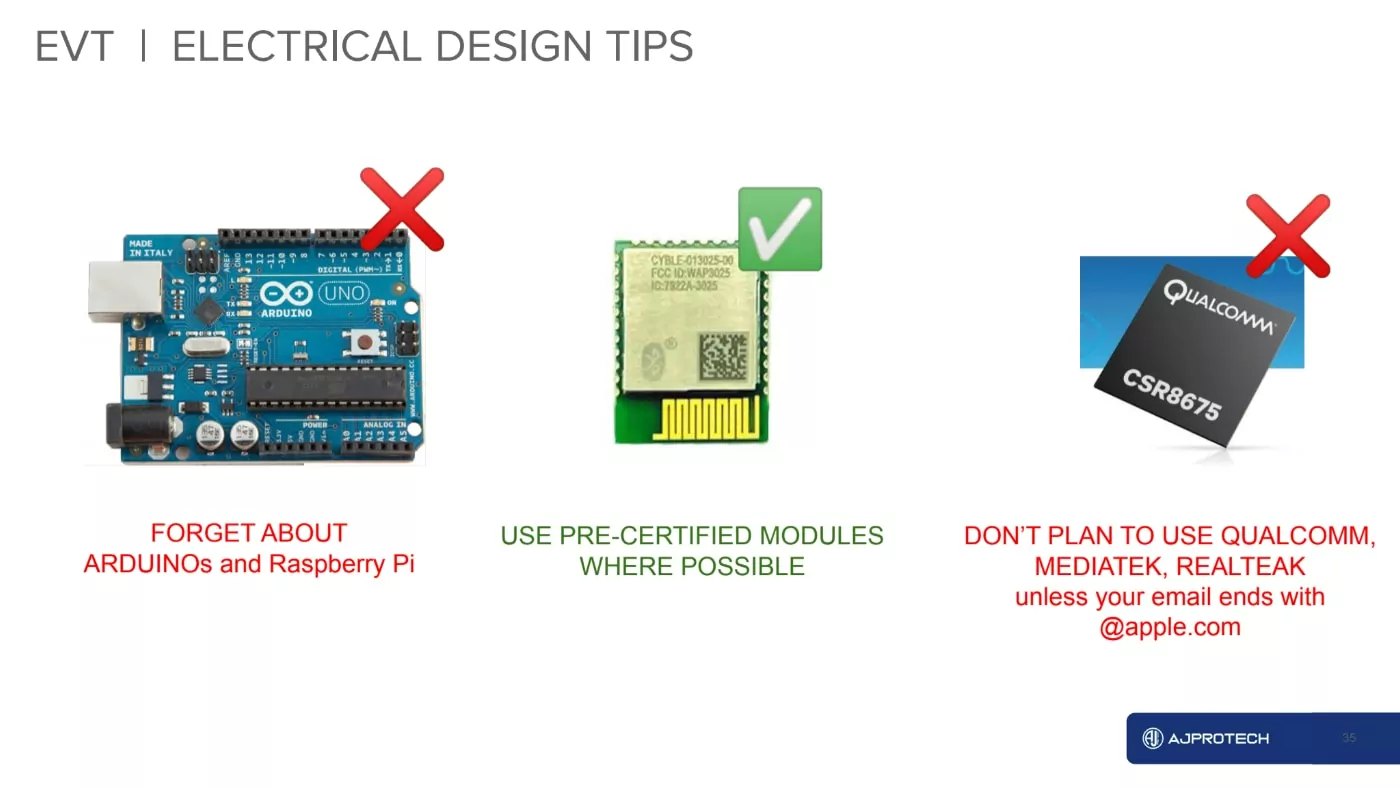

- At the Engineering Validation Test (EVT), forget about Arduino / Raspberry Pi. They are nowhere near to be used in a product. Use evaluation boards instead. This way you use production-grade components from the start

- Use pre-certified radio modules where possible. They allow you to simplify your development and streamline FCC compliance.

- And finally, if your email doesn’t end with “apple.com” or another big company, don’t plan to use QUALCOMM, MEDIATEK and REALTEK components. They are really painful to work with and even to get some documentation and samples.

A few more recommendations for electrical engineers:

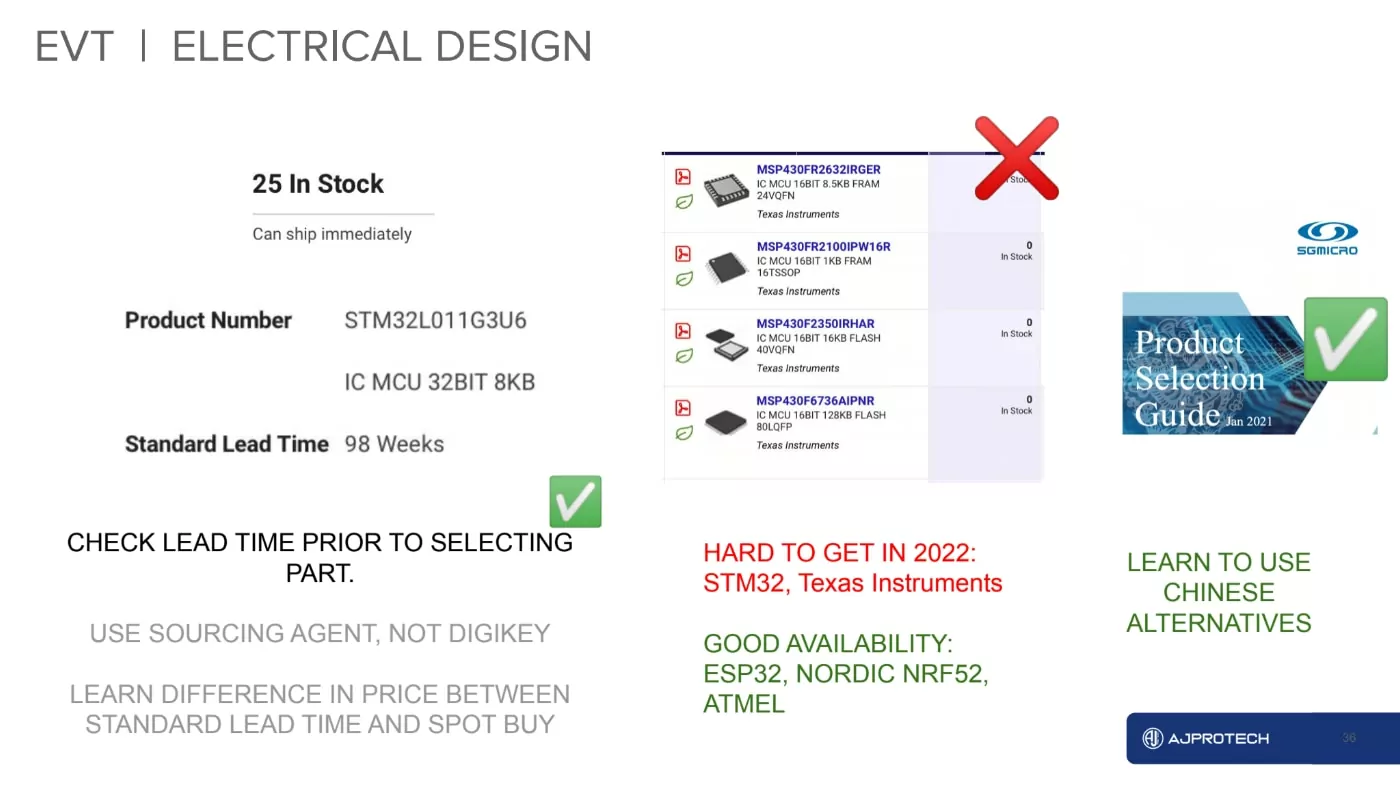

- Check lead time prior to selecting parts.It is especially important in 2022. Most of our designs are driven by availability, not by the functionality. It’s the ugly truth these days.

- Some components, which are really hard to get these days are: STM32, Texas Instruments. We switch them for ESP32, NORDIC NRF52, and some ATMEL components, where possible

- And finally, learn how to use Chinese alternatives.Many Chinese manufacturers have pin to pin replacements that perform the same as TI and can be procured much easier to get these days.

Stay tuned for the next video where we’ll talk about the next step – MECHANICAL DESIGN

More about our Product Development Process

Contact us to discuss your project

AJProTech team

Ajprotech.com

A few more recommendations for electrical engineers:

A few more recommendations for electrical engineers: