About Us

Our Hardware

Your Vision

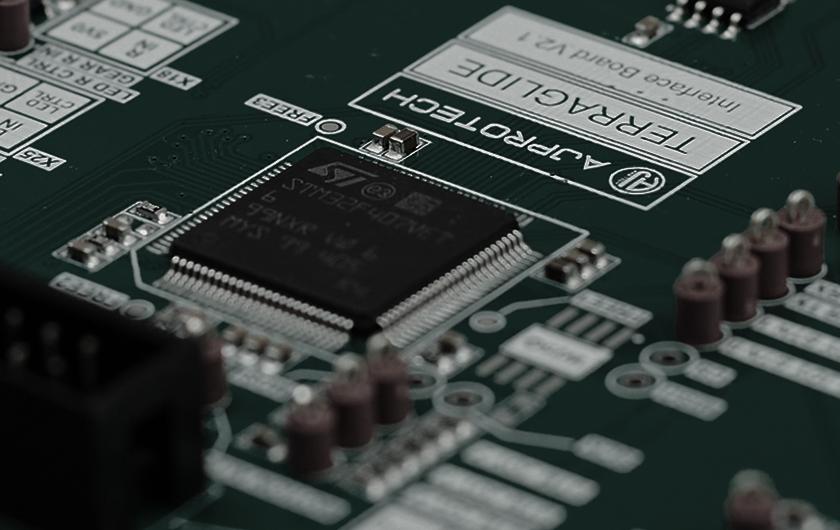

Real Products

Our Journey

Our Case Studies

Let's Talk About Your Project

Please fill out the form and we'll get back to you shortly

Frequently Asked Questions

How is my Intellectual Property (IP) protected?

We understand the importance of IP for innovative products. Before sharing confidential information, we sign an NDA (Non-Disclosure Agreement). You, as a client, own the results of all work with us.

Where will my products be manufactured?

High volume, low cost products (e.g. Consumer Electronics) are typically manufactured in South East Asia - China, Taiwan, Vietnam. Low volume, high cost products (e.g. Medical devices, Industrial equipment) may be made in the USA. We can evaluate production cost so you make educated decision. We can make introductions to manufacturers we worked previously but it is your decision which factory you choose.

Why working with AJProTech and not with Chinese manufacturers directly?

First, when a Chinese manufacturer develops a product for you, often at low cost, they own the IP. If you ever need to move production to another factory or expand your manufacturing, it often requires creating all design files from scratch.We make your product manufacturer-agnostic - you can work with any Contract manufacturer of your choice.

Second, when working with a Product Design studio, like AJProTech, you own the IP and design files. We teach you to strategically distribute manufacturing of parts on different factories to ensure your product can not be copied by either of those.

Third, most manufacturers are great at making products cost-effective. However, most factories also benefit from re-using the same technologies they are familiar with. In many cases, that makes the product less innovative. Often, manufacturers use components that are best for their profit margins.

What product development services do you offer?

AJProTech covers entire product development - from Idea to Mass Manufacturing. Hardware design is our core strength.

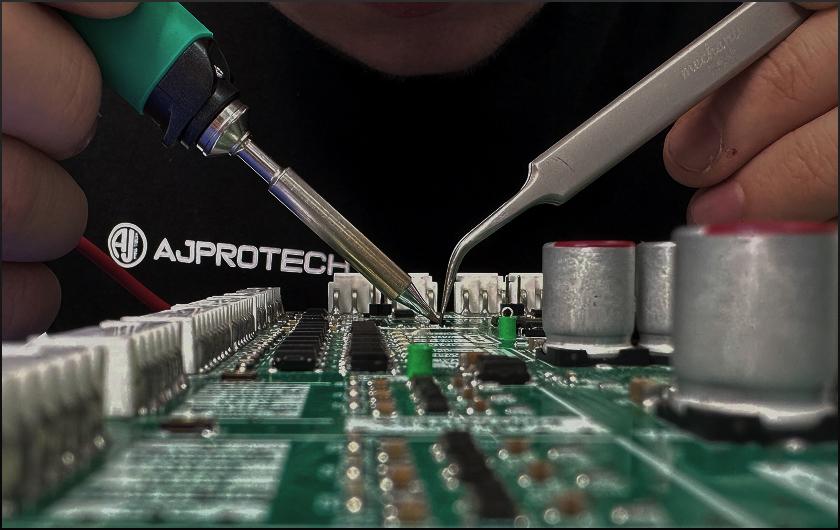

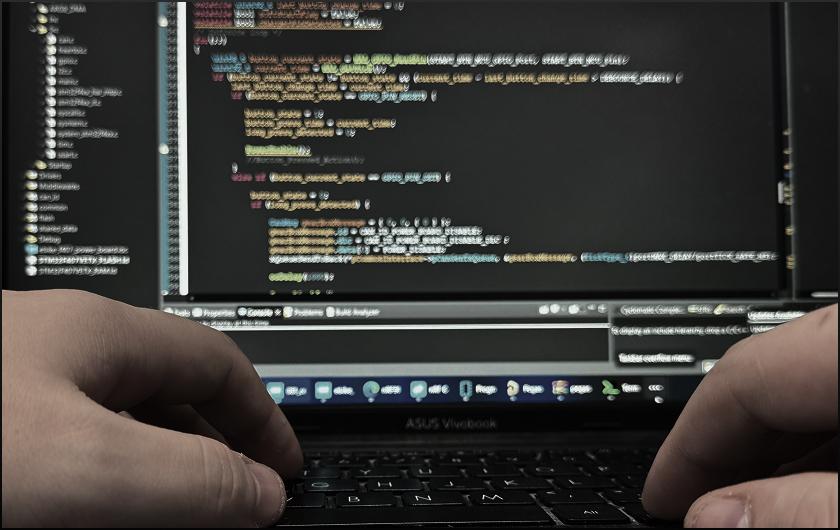

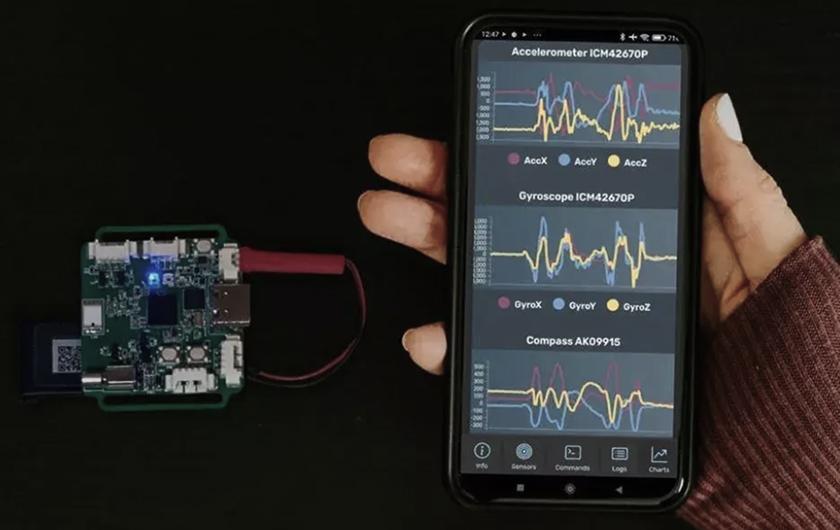

We design Electronics - PCBs, Embedded Firmware.

We create Industrial and Mechanical designs from plastic and metal.

We develop Mobile apps that connect to your smart products

We do Design for Manufacturing optimization with Contract Manufacturers

And we communicate with Factories to ensure your product is ready for production

What is a typical development timeframe?

Unlike software development, where new releases can be done every week, cost of change in Hardware is often measured in months. Proper design process is essential for a successful product. Our products are designed in sprints: MVP, EVT, DVT, PVT.

Most products can be prototyped in 10-16 weeks.

Typical time to get a product ready for mass production is 10-12 months.

How much product development costs?

Each project is unique in its complexity and design needs - there is no one-size-fits all. To get a proper estimate, we encourage you to schedule a free 30-minute consultation with our team. We may give you an estimate of design cost and development timeframe right on the call.

Can AJProTech create prototypes?

Absolutely! We have a fully equipped prototyping lab with PCBA assembly equipment, 3D printers and machining tools. We quickly produce, test, and iterate prototypes.

When silicon molding, laser cutting, or CNC bending are required, we work with local partners to get parts done and delivered to our lab for final assembly

Contact Us

Headquarters: Los Angeles, CA

26565 Agoura Road, Suite 200,

Calabasas, CA 91302

R&D and Manufacturing

New Taipei City

Wenhua 2 Road, Linkou District

Software design

Almaty