Mechanical Design and Industrial Design Services

INDUSTRIAL and Mechanical DESIGN

Industrial and mechanical design are two key components of consumer electronics production. Industrial design is responsible for the aesthetics and user experience of a device, while mechanical design involves the engineering, materials and fabrication of the device’s components.Engineering is a complex process when it comes to product design. By using a complex approach to engineering, design can achieve superior results and create products that meet the exact needs of the customer.

When industrial and mechanical design are considered together, it allows for a comprehensive design process that takes into account both the aesthetics and functionality of the product. This ensures that the product will be attractive, ergonomic, and reliable.

industrial design process

discovery

concept creation

concept refinement

manufacturing support

architecture

design

build

mechanical engineering process

Our design team boasts the specialized skill set and extensive experience required to develop revolutionary electronics products for both consumer and industrial applications. By bridging the gap between the desired features, user interaction, and the eventual functioning hardware, we strive to deliver the best possible results.

INDUSTRIAL DESIGN

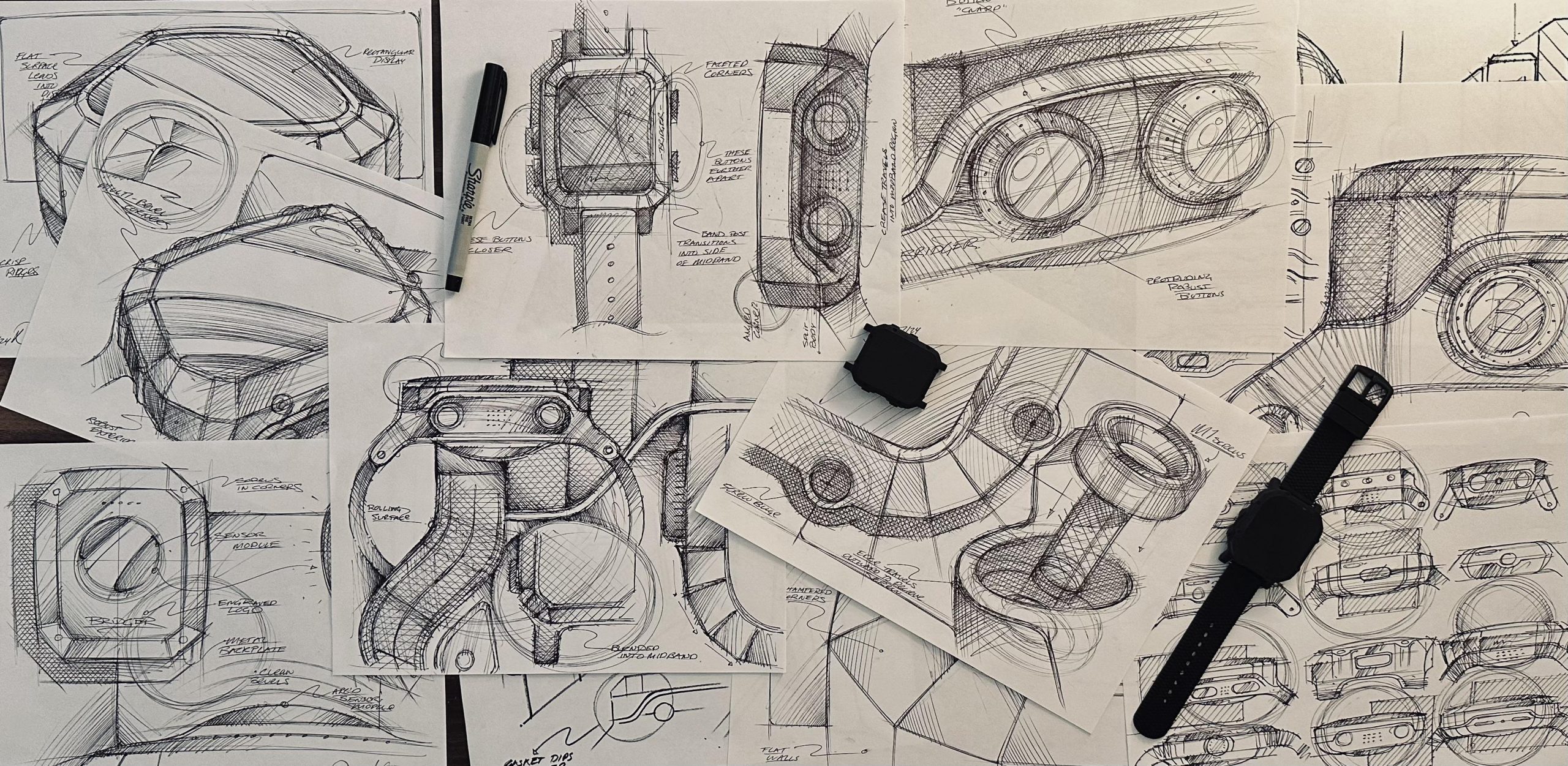

Industrial design focuses on creating an aesthetically pleasing product that is ergonomic and easy to use. It considers the product’s shape, color, textures, materials, and user interface. It also takes into account how the product will be displayed and marketed, as well as how the product can be used in different environments. We take a consumer-centric approach when designing industrial products. Using a rapid process to create these designs, which involves gathering feedback from consumers, we understand their needs, and leveraging the latest technology to develop innovative solutions.

Сollect requirements. Analyze competitors and similar products (1-2 weeks).

Сreate 20-30 early design sketches for initial discussion (1-2 weeks).

Usability testing using early low-fidelity prototypes - carton, plywood or 3D printed (1-2 weeks).

Select 5-7 design variants for more refined sketching (1-2 weeks).

Select 2-3 variants for detailed design. Prepare first batch of 3D renders (2 weeks).

Usability testing using medium-fidelity 3D printed prototypes (1-2 weeks).

Create high-fidelity 3D renders in CAD. Early CFM review (1-2 weeks).

High fidelity prototypes done with CNC machining or 3D printing with post-processing (2 weeks).

Customer beta-testing. Feedback gathering. Adjustments as needed.

Mechanical engineering

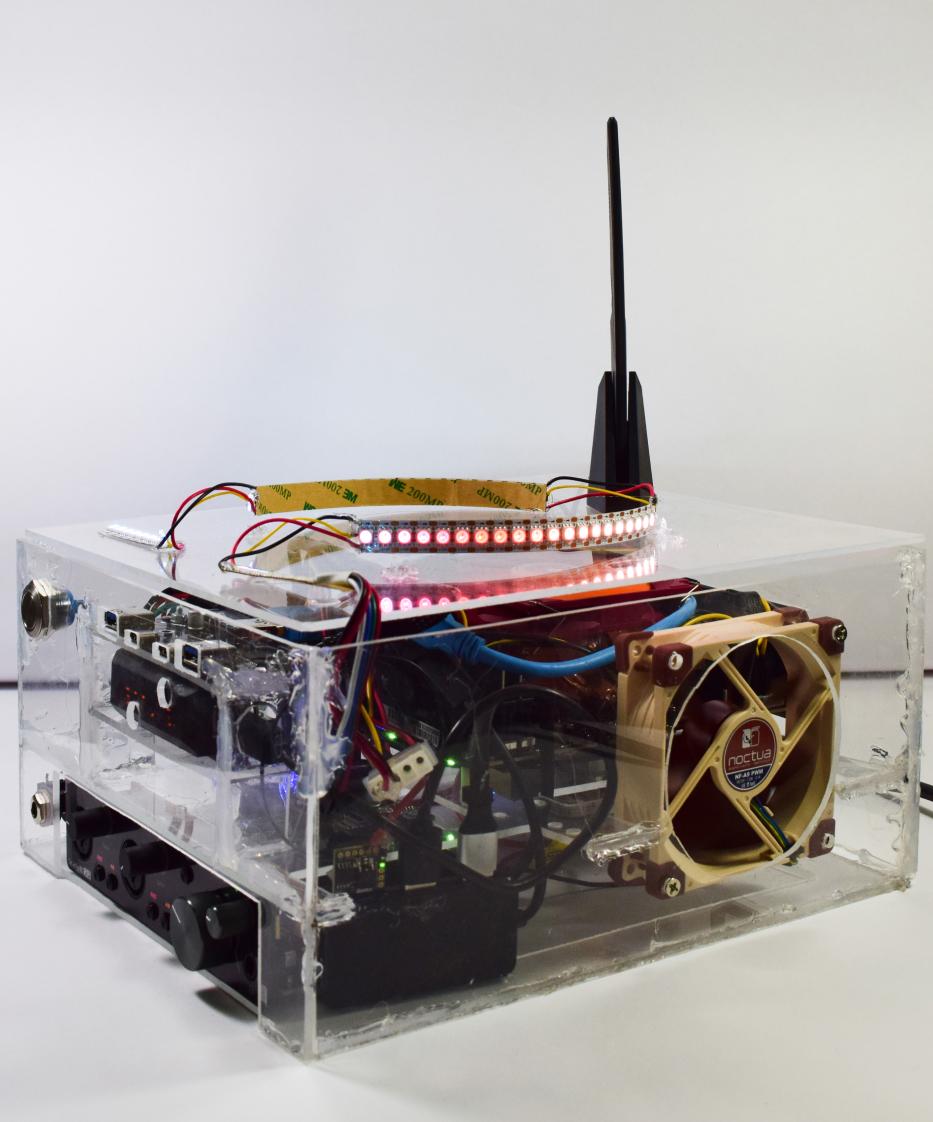

We create custom product designs and enclosures made from a variety of materials, including plastic, metal alloys, and fabrics. Our team of experienced designers have the expertise to craft bespoke solutions that meet your exact requirements.

- Product research and sketching

- Industrial design

- Detailed engineering in CAD

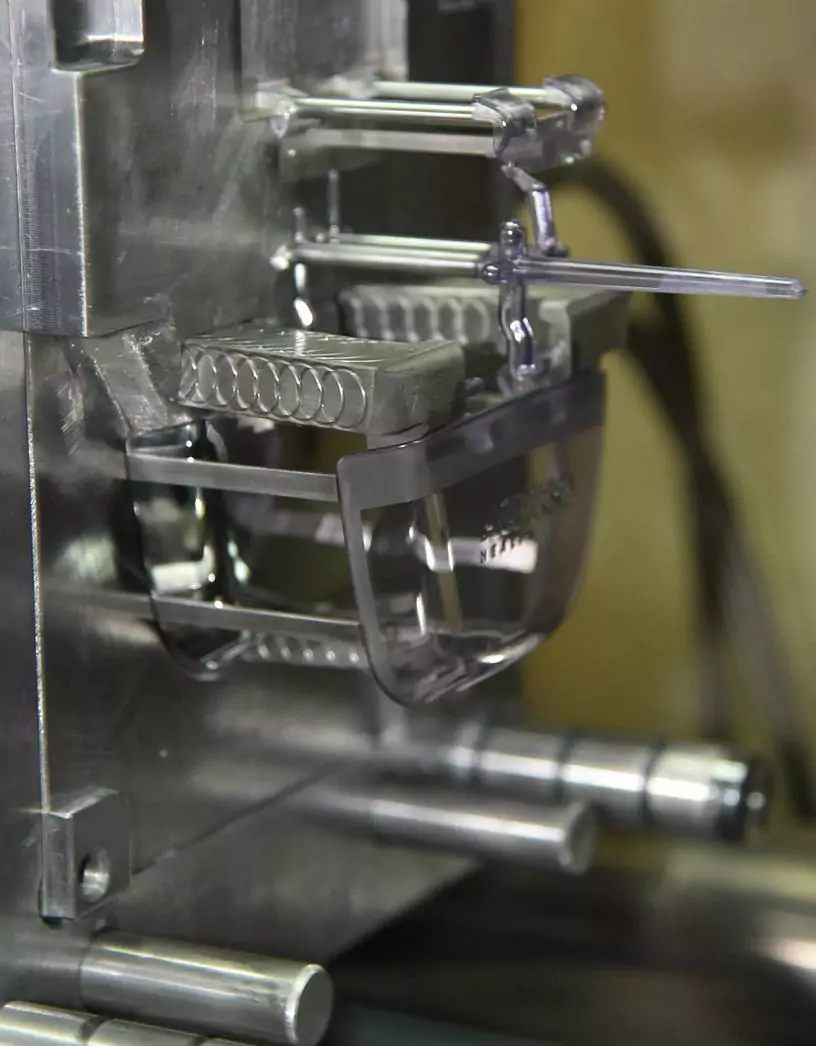

- Rapid prototyping using 3D print / CNC machining

- Stress and Failure analysis

- Engineering Validation samples (EVT)

- Design Validation and Tooling

- Production Validation (PVT) and start of Mass Production

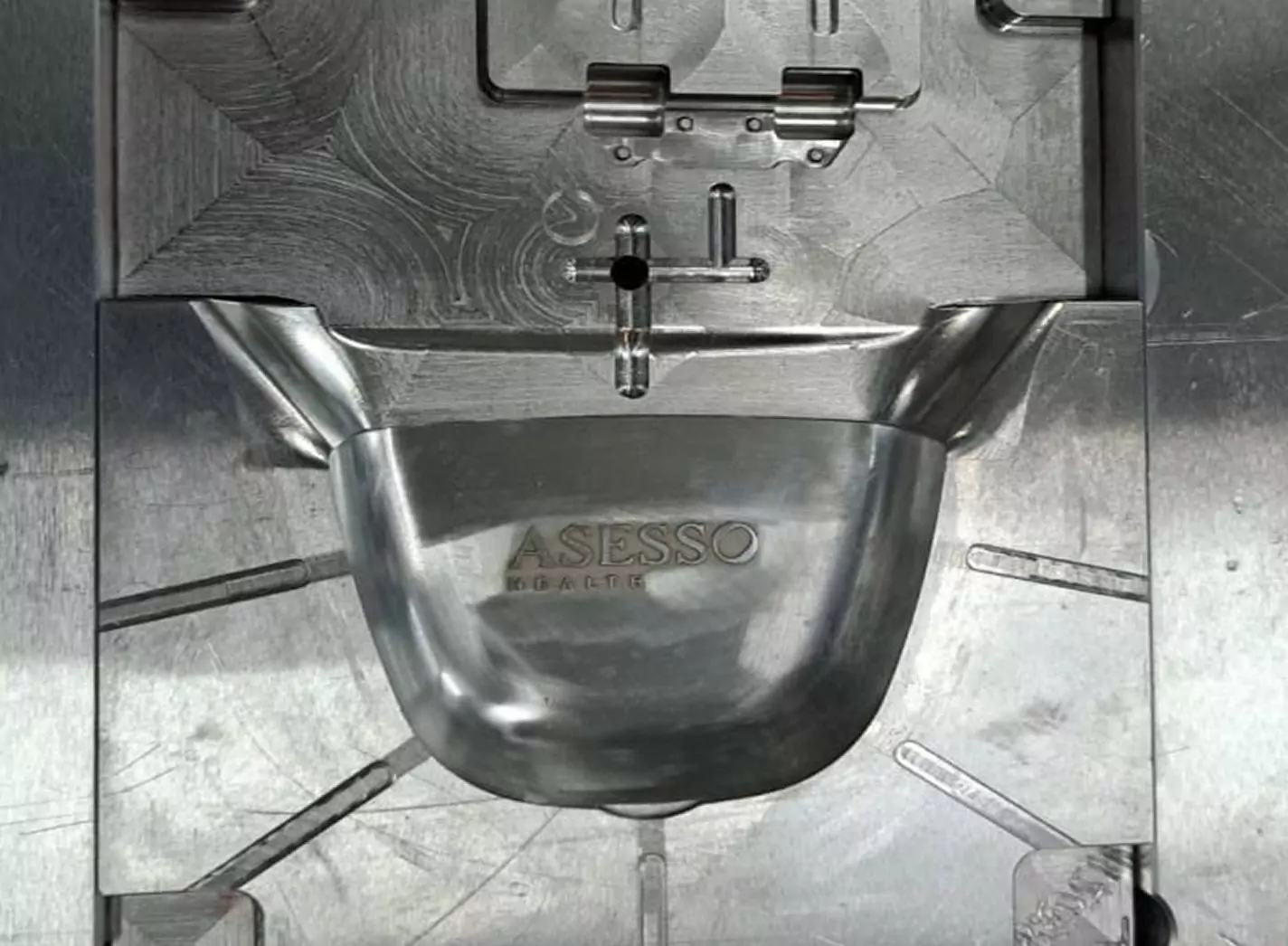

Plastic enclosures are typically produced by injection molding. Our experts have tens of thousands of unit samples produced

- Industrial design and CMF (Color / Material / Finishing)

- CAD Design

- Rapid prototyping using 3D print or Silicon molding

- Design for Manufacturing (DFM)

We have fully equipped prototyping lab to rapidly prototype and test new concepts. We have four 3D printers, milling machines, and expansive network of prototyping partners.

- 3D printing - when rapid validaiton is needed

- CNC machining - high quality samples out of solid piece of material

Our prototyping partners assist with:

- Silicon molding - when you need to impress someone with production-looking samples

- Laser Cutting and CNC bending

- Welding, Painting, Assembly

We love working with metal to create robust mechanical structures.

- Various materials - we work with Aluminum, Steel, and Alloys

- Sheet metal designs - when enclosure is cut, bend, and welded from sheet metal

- Stress and Failure analysis - simulate every operation condition

Our metal designs are used at Oil and Gas facilities, Factories around the world, and on

parking structures in Manhattan.

We help companies move from prototype to full-scale production at their selected Contract Manufacturer. Our clients own the IP and may work with any Manufacturer of their choice

- Mechanical DFM review

- Contract Manufacturer selection

- Injection molding design overview

- Manufacturing Support

- Quality Control

Rapid prototyping

We offer rapid prototyping services to help you get your product to market faster. Our CNC machining and silicone molding processes create high-quality mechanical prototypes with minimal fixed expenses.

These samples can be used as trade show units or presented to early customers. With our fast MVPs, you can quickly launch your product and get it out into the world.

Design for Manufacturing

AJProTech provides innovative design for manufacturing services to help your business reduce expenses while accelerating the development of products. We utilize advanced 3D CAD, FEA, and CFD simulation tools to optimize product design and analyze component manufacturability. Our comprehensive engineering analysis, prototyping, and production support services are designed to expedite your product introduction to the market, enabling you to get your product to market faster and more cost-effectively. Launch your product quickly with increased efficiency and lower costs with AJProTech.

Frequently asked questions

AJProTech specializes in mechanical design services, electronic product development, and hardware product development. Our range of services includes concept design, 3D CAD design, mechanical engineering services, and engineering design services, targeting automation, automotive, and various other industries.

Excellence in our mechanical design services is ensured through rigorous quality checks, adherence to industry standards, and leveraging the latest in modeling and drawing technology. Our expertise in design engineering allows us to deliver top-notch design solutions that meet and exceed client expectations.

Yes, with our comprehensive design engineering and mechanical design engineering services, coupled with our expertise in system design and electromechanical automation, we can manage complex product designs. Projects are carried out within our design engineering services company framework that accommodates a wide range of product engineering needs, from initial concept to final product development.

AJProTech stands out due to our integrated approach that combines mechanical engineering services with electronic product development, our commitment to excellence, and our broad industry experience. Our services include end-to-end solutions for mechanical and electronic product design, making us a preferred engineering services company for clients looking for comprehensive design solutions.

Yes, we provide mechanical design and engineering services tailored to the automotive industry's needs, encompassing thermal management system design, automotive equipment development, and automation solutions. Our expertise in CAD and mechanical design engineering services enables us to deliver innovative and efficient solutions to automotive clients.

The benefits of selecting AJProTech for CAD and mechanical design services include access to a team of experts with in-depth knowledge of the latest CAD technologies, industry-leading design solutions, and comprehensive support from concept design through to product completion. Our approach ensures that mechanical design services are carried out with efficiency, precision, and innovation.

AJProTech ensures that product design projects progress smoothly by applying project management excellence across all stages of development. We employ systematic design processes, maintain clear communication with clients, and utilize agile methodologies, ensuring that all design services are delivered on time and within specification. Our engineering services company values transparency and collaboration, keeping clients informed at every step.

A myriad of industries can benefit from our design engineering expertise, including but not limited to automotive, automation, consumer electronics, healthcare, and manufacturing. Our versatile engineering design services and mechanical design services are tailored to meet the unique needs and challenges of diverse industry sectors.