Oil Pump System

SYSTEM OVERVIEW

Heart of the system Solid State Pump by Piezo Motor. Pump including all Power Electronics is located deep underground and can withstand harsh temperatures of up to 150˚ C.

Controller and HMI interface units are located in regular accessible industrial cabinet

CONTROLLER UNIT

Custom embedded controller and monitoring system. Incorporates Signal Generator, Amplifier Controller, and Data Acquisition system.

Uses Proprietary long-distance transmitter to modulate control data in power cable (5 km = 15,000 ft).

32 bit ARM

Microcontroller

Signal

Generator

Data

Transmitter

Ethernet

USB

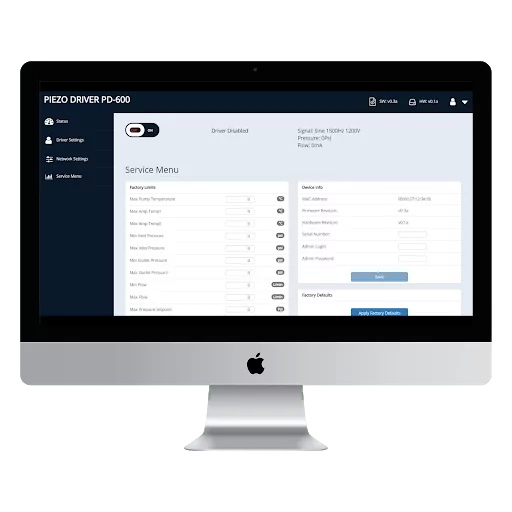

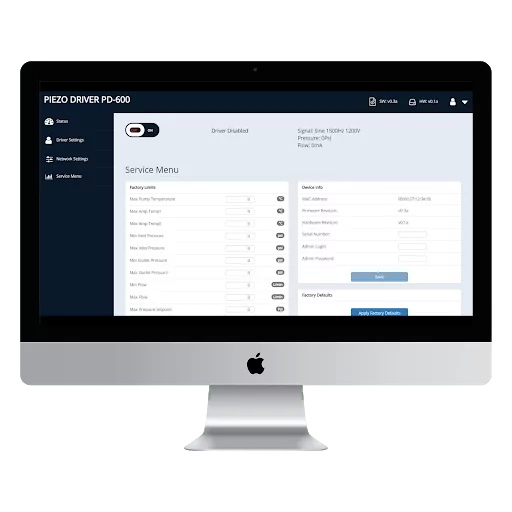

USER INTERFACE

Embedded Web Server allows access to pump from HMI unit in the cabinet or any place in the world

- Pump settings control

- Signal settings

- Data acquisition

- Multiple access levels

- Log file

- Remote firmware update

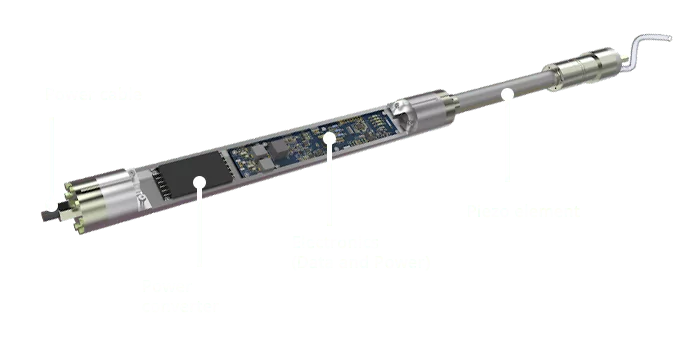

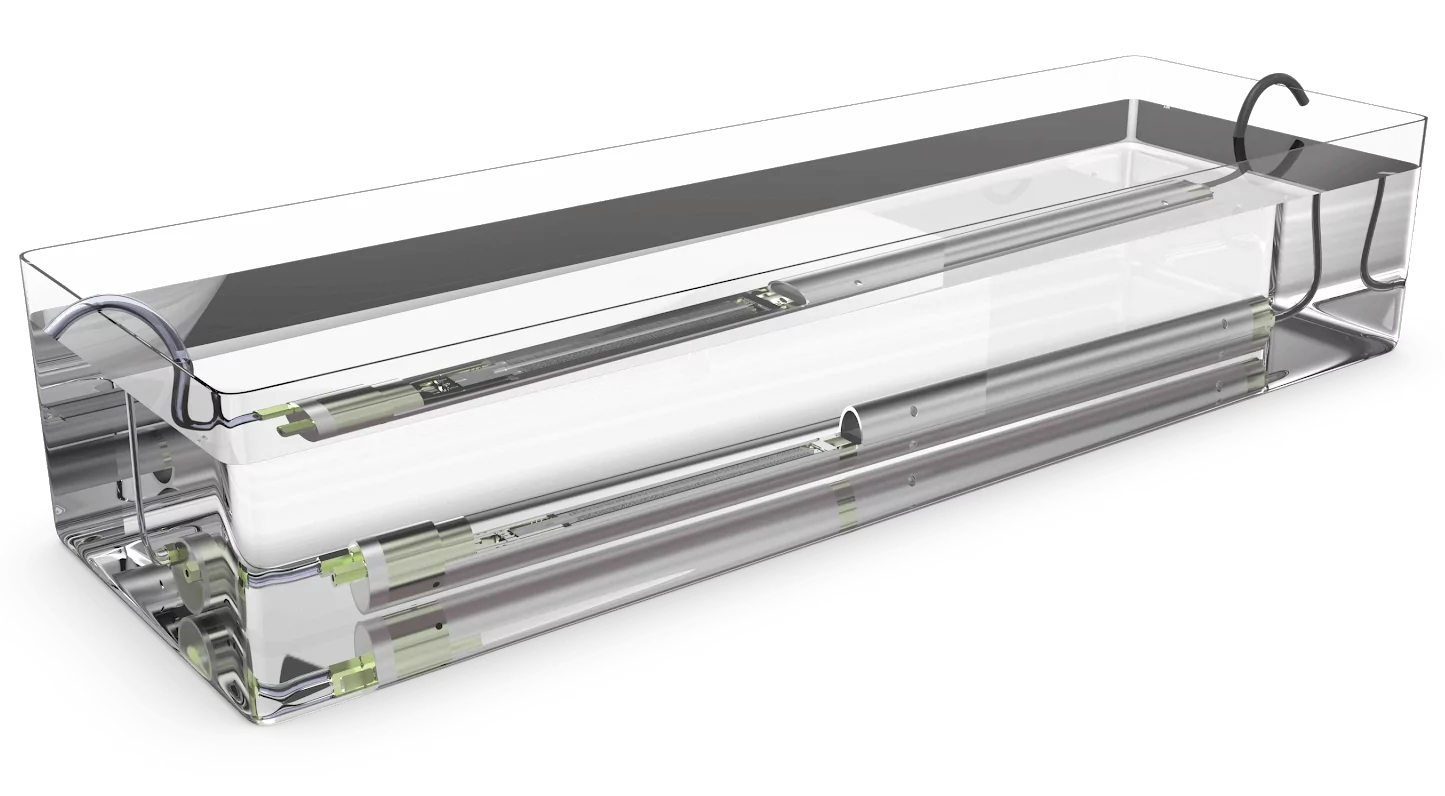

HIGH-POWER SOLID STATE ACTUATOR

ACTUATOR uses high-power piezo motor that oscillates at high frequency to force the liquid through the output valve.

Single moving part and no bearings allow maximum reliability.

Incorporates Data Receiver and Power Electronics with industrial-grade parts

Piezo

actuator

Power

Electronics

Temperature

Up to 150˚ C

PIEZO PUMP SPECIFICATIONS

Output pressure up to

10,000 psi

Flow rates up to

5 liters/minute

HOW IT WORKS

Using only a single moving part, Solid State pump has no bearings and require no lubrication.

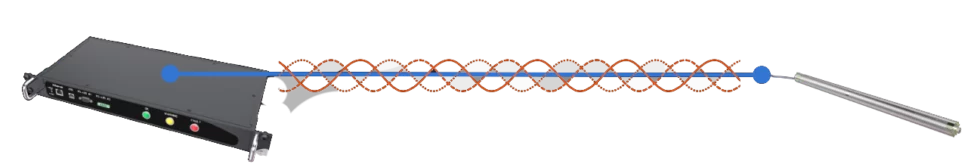

DATA TRANSMISSION

System uses single cable to transfer Power and Data from Controller to Actuator.

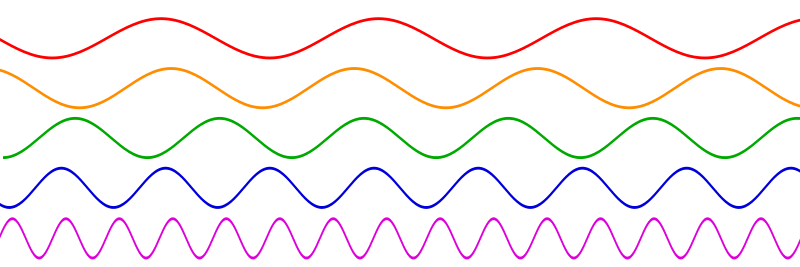

Frequency modulation is used to inject control data into power cable

Data is decoded upon receipt

OUR TEAM PERFORMED

PRODUCT DESIGN

CONTROLLER designed into industry-standard 19” 1U crate. Power Amplifier is packed into 2” crate.

POWER ACTUATOR consists of piezo motor and all electronics sealed into steel tube and filled with compound for cooling.

ELECTRICAL DESIGN

Controller is a custom industrial system with embedded web server for remote access.

Downhole unit is a piezo actuator, data transmitter, and power supplies. Designed and tested to withstand 120C ambient.

Power electronics system to generate high-voltage output signal for piezo actuator and compensate for signal distortion.

EMBEDDED FIRMWARE WEB SOFTWARE

Embedded real-time control firmware for signal generation, distortin compensation, data acquisition

Embedded web server for remote control and diagnostics of pump. All parameters are transmitted real-time.

CURRENT STATUS:

Production