Industrial IoT Development Services

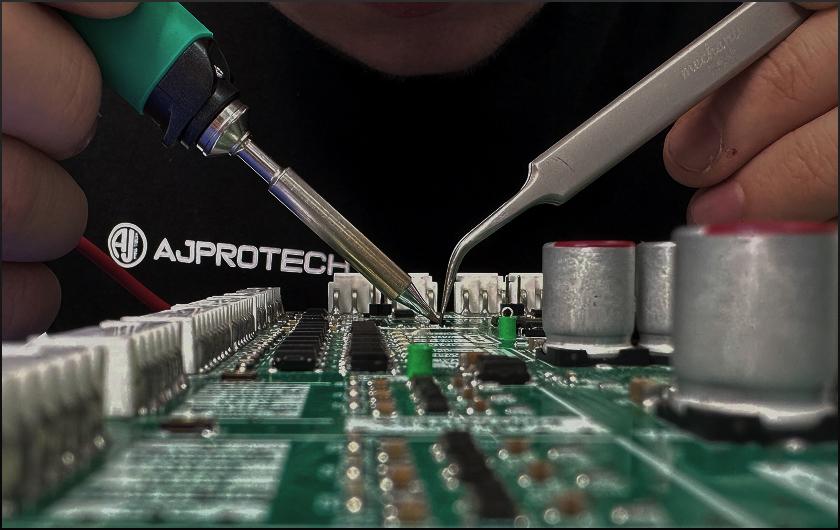

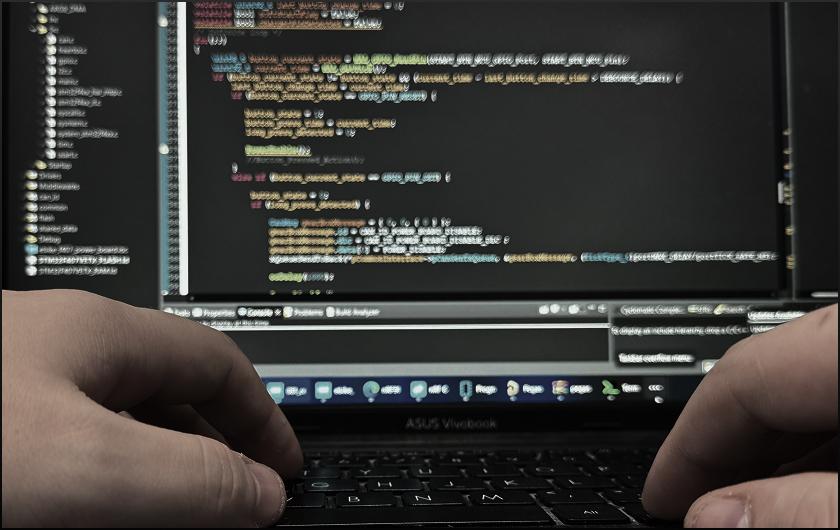

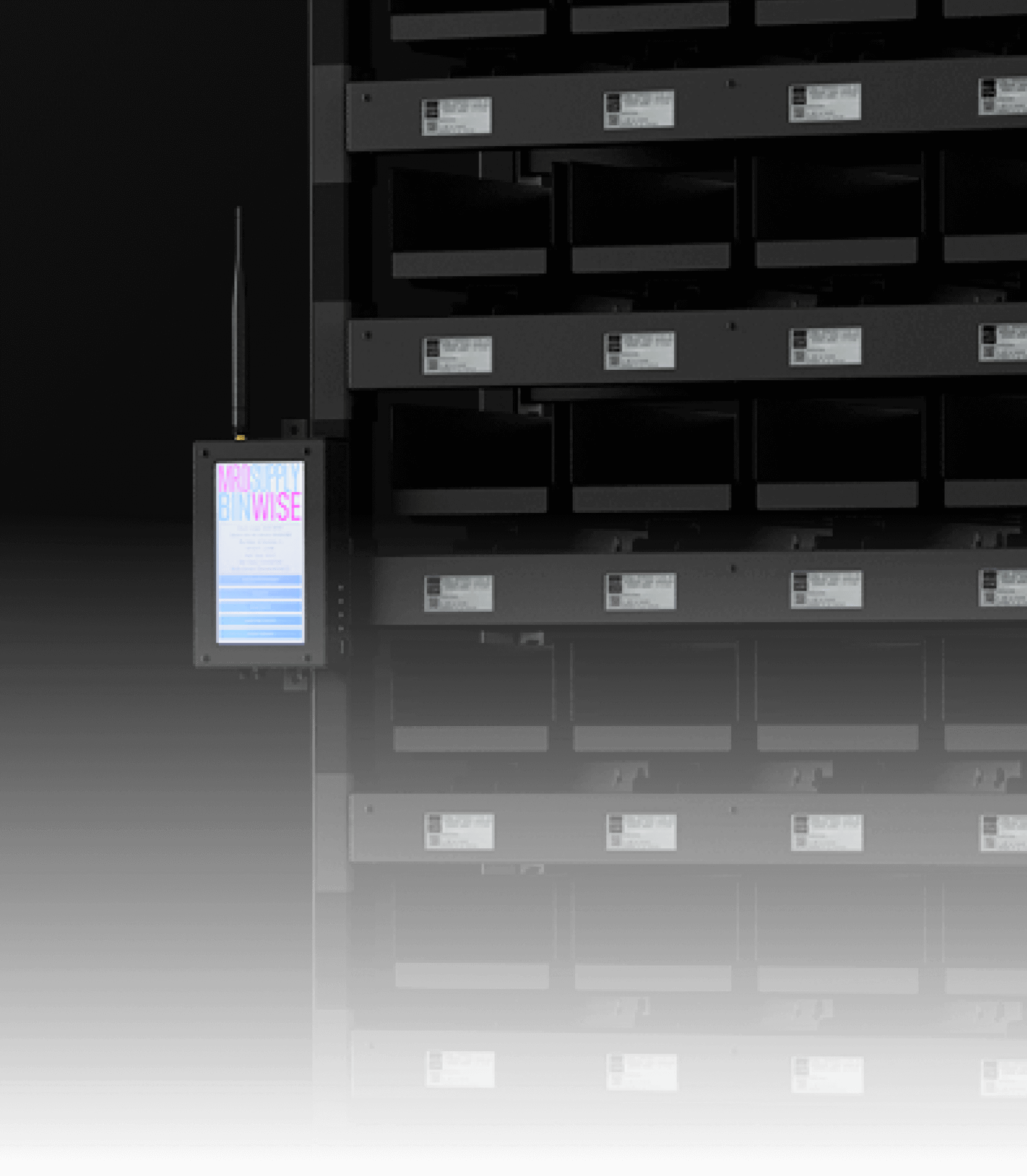

AJProTech accelerates IIoT adoption by creating secure, scalable solutions for industrial applications. We design custom modules, gateways, and HMI interfaces that connect machines, actuators, and PLCs into a unified IIoT platform. Our technology helps companies collect and analyze data for smarter decisions and predictive maintenance.

From prototype to deployment, our expertise in hardware and software delivers robust IIoT projects that power the industrial internet. We help businesses embrace connected technologies to improve efficiency, reliability, and performance. Together, we drive innovation and sustainable growth across modern industry.

Industrial IoT Development & Engineering Services

Industrial IoT development process

Feasibility study

- Solution research

- Product Specification

- Component selection

- Early industrial Design

- Cost estimate

Proof of concept ”Work like” prototypes using development kits

Early customer feedback

Prove Core Technologies

2 - 3 months

Engineering Validation

- Detailed engineeing

- Industrial Design

- Electronics development

- Embedded firmware

- Mechanical design

Engineering samples using rapid prototyping, 10 - 50 pcs

Customer Beta testing

Pre-compliance testing

Second iteration, if needed

EVT

Engineering Samples Meet Specs

5 - 6 months

Design Validation

- Select Manufacturer (CM)

- Design for Manufacturing

- CMF (Color, Materials, Finishing)

- Electronics design ECO

- Firmware / Software finalization

- DFM for Mechanical parts

Tooling for Mechanical parts CM does product prototyping using tooling, 50- 100 units

Compliance tests (FCC, UL, CE)

Deliver samples to beta testers

DVT

Pre-Production Samples Ready

4 - 5 months

Production Validation

- Supply chain optimization

- Final tooling for all parts

- Prepare Functional tests

- Create test jigs

- Fault and yield review

- Order parts for first batch

Setup manufacturing process CM applies mass-production techniques, 500 - 1000+ units

Final compliance tests

Deliver product to early backers

PVT

Production Process Validated

3 - 4 months

Our Case Studies

10 Years of Excellence

AJProTech extends beyond delivering exceptional IoT solutions for our clients. We are committed to fostering a collaborative community where knowledge is shared and opportunities for growth are nurtured. By freely sharing our expertise and insights, we aim to contribute to the collective advancement of the IoT industry, including its growing applications in the wellness sphere, and to inspire others to reach new heights.

AJProTech has developed an innovative approach to streamlining the manufacturing process of IoT devices, reinforcing our position as a leader in the industry. Our expertise in IoT development services has earned us esteemed recognition as a top-rated company across various platforms, including trusted partnerships and a 5-star rating on Clutch. Increasingly, our solutions are being leveraged in the wellness sector, where connected technology is transforming health, fitness, and overall well-being.

Alex Gudilko, the CEO and Founder of AJProTech, regularly shares his insights into the hard tech and wellness technology sectors in Forbes. With a focus on emerging technologies, engineering advancements, and business strategies, Alex’s articles offer valuable perspectives for navigating the evolving intersection of IoT and personal wellness. Through his contributions, he aims to foster understanding, inspire innovation, and empower professionals across industries.

Frequently Asked Questions

What are Industrial Internet IoT Development Services?

Industrial Internet IoT Development Services involve creating solutions that connect devices and systems within an industrial setting to enhance operational efficiency. These services encompass the design, development, and deployment of IIoT systems, enabling industrial companies to harness data from machines, sensors, and equipment for better monitoring, control, and predictive maintenance. By utilizing IoT technology, companies can automate processes, ensuring a seamless flow of information and a significant reduction in downtime.

How does IoT improve industrial operations?

IoT improves industrial operations by enabling the real-time monitoring of equipment and machines. Through the integration of IIoT devices such as sensors, actuators, and edge devices, organizations can collect and analyze data to improve decision-making processes. This leads to enhanced safety, optimized process performance, and improved power management. Furthermore, IoT applications allow for predictive maintenance, thereby minimizing unplanned outages and extending the lifespan of industrial machines.

What are the key benefits of adopting Industrial IoT?

The key benefits of adopting Industrial IoT include improved efficiency, enhanced safety, and reduced operational costs. By connecting devices and implementing IIoT solutions, organizations can automate routine tasks, ensuring that industrial processes run smoothly. Moreover, real-time data collection and analysis allow for quick responses to any irregularities, improving the overall industrial setting. Companies can also leverage automation for better resource management, ultimately contributing to higher productivity levels.

Latest News

Let's Talk About Your Project

Please fill out the form and we'll get back to you shortly

Contact Us

Headquarters: Los Angeles, CA

26565 Agoura Road, Suite 200,

Calabasas, CA 91302

R&D and Manufacturing

New Taipei City

Wenhua 2 Road, Linkou District

Software design

Almaty