The Challenge

With the growth of the number of vehicles, there are so few parking aces in big cities. There

are

solutions to this issue - multilevel parking slots.

An overwhelming majority of those solutions are manual - they can only move up and down and

if you'd

like to get the car from the upper level - you need to unpark the bottom one that's

underneath yours.

There are a small number of automatic solutions from German manufacturers, but they are more

expensive and

if at least several systems are needed, it already makes financial sense to make your own

system.

It can be better, cheaper and bring the most value to the people and big cities. Here at

AJProTech we

know how to make all this into reality.

The Solution

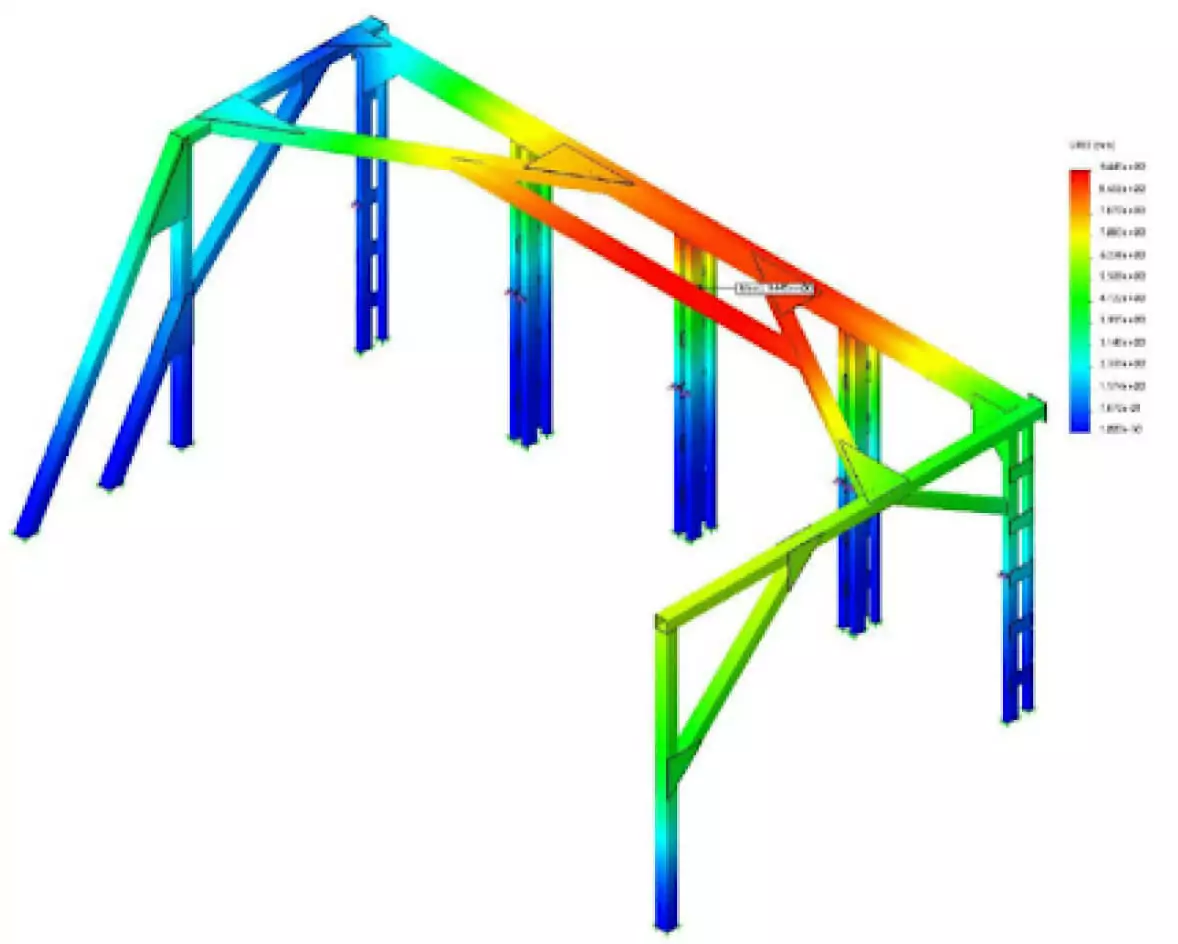

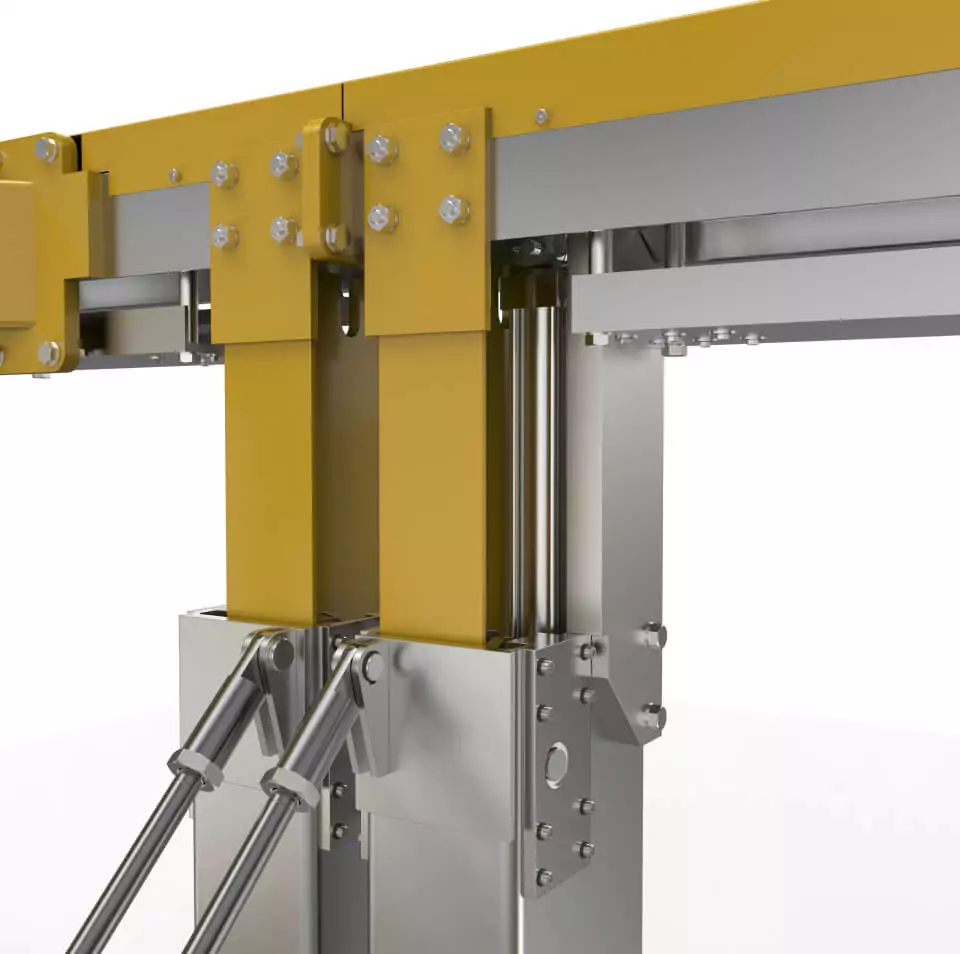

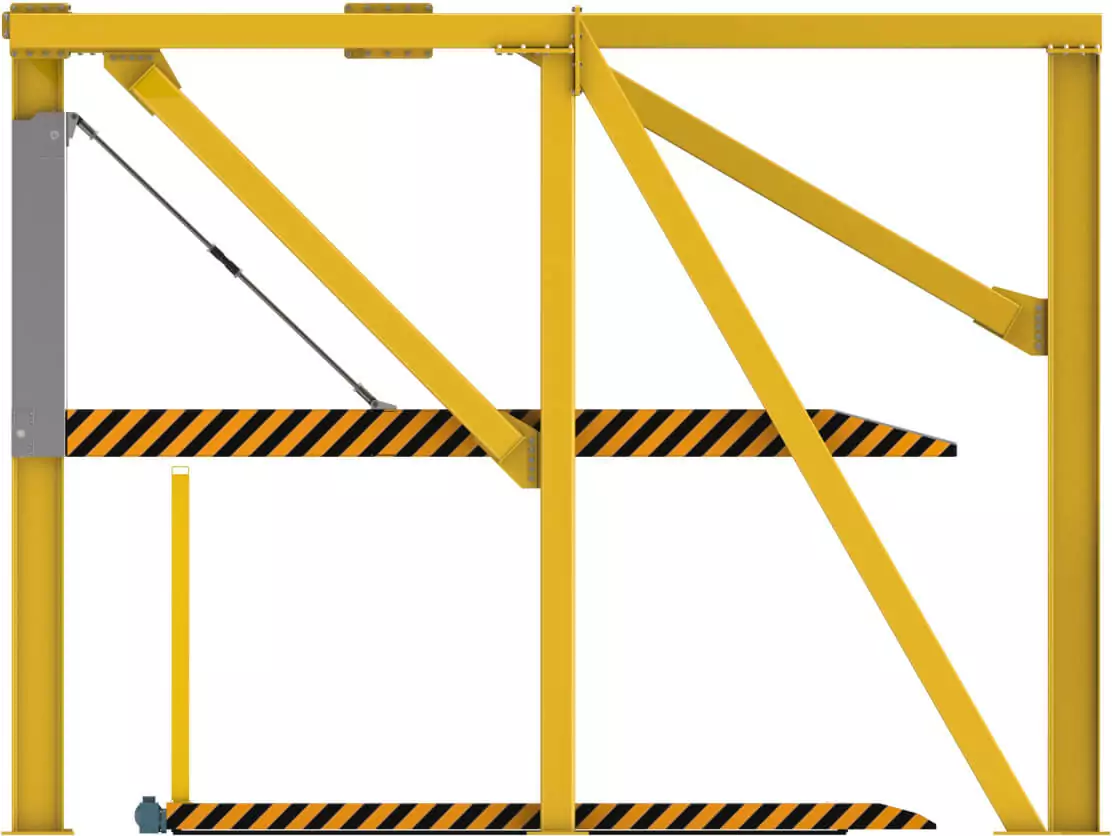

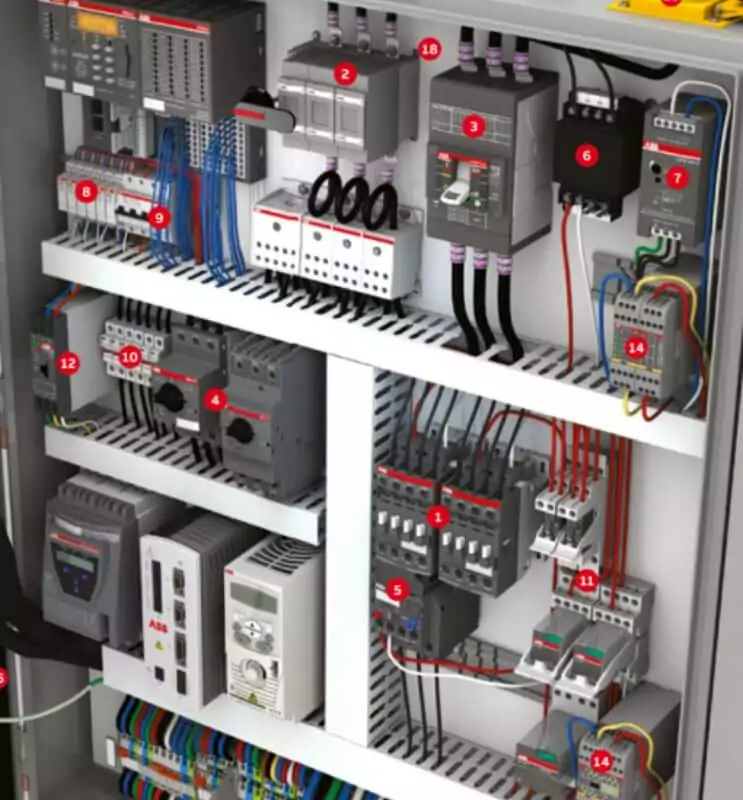

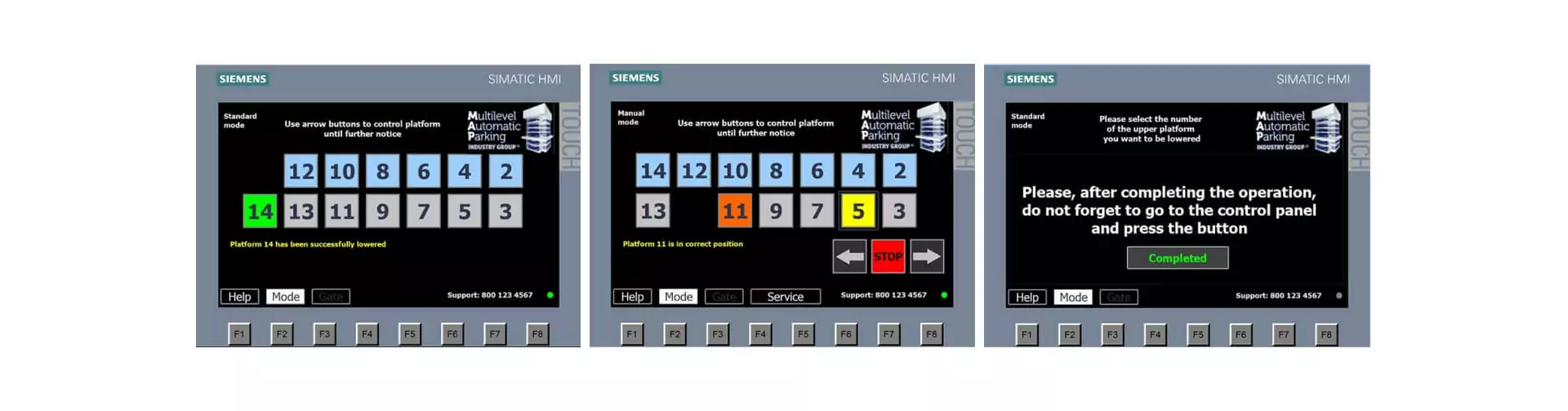

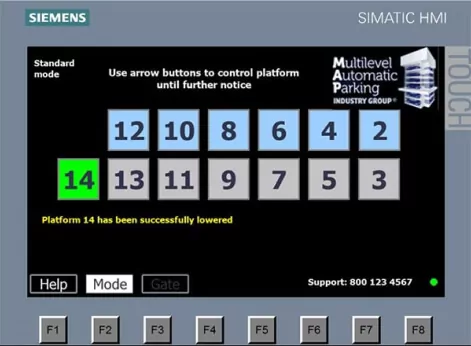

In collaboration with the MAP Group, a well-known New York parking operator, we have

developed a

semi-automatic multi-level parking system. It is a modular two-level system that allows you

to park up to

13 cars on 2 levels.

The developed solution allows residents of residential areas in Manhattan with a minimum

occupied area,

to park and pick up cars on their own, or significantly speed up the work for valet parking

personnel.